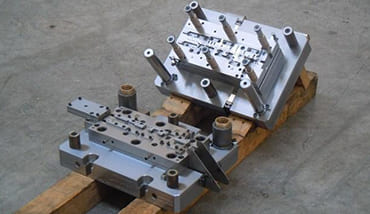

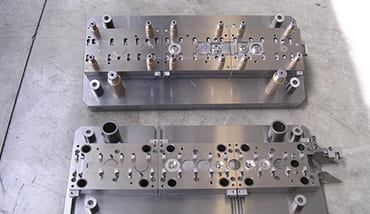

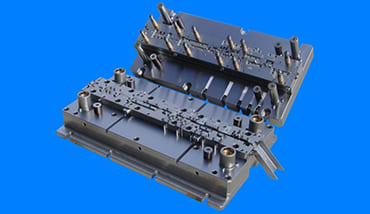

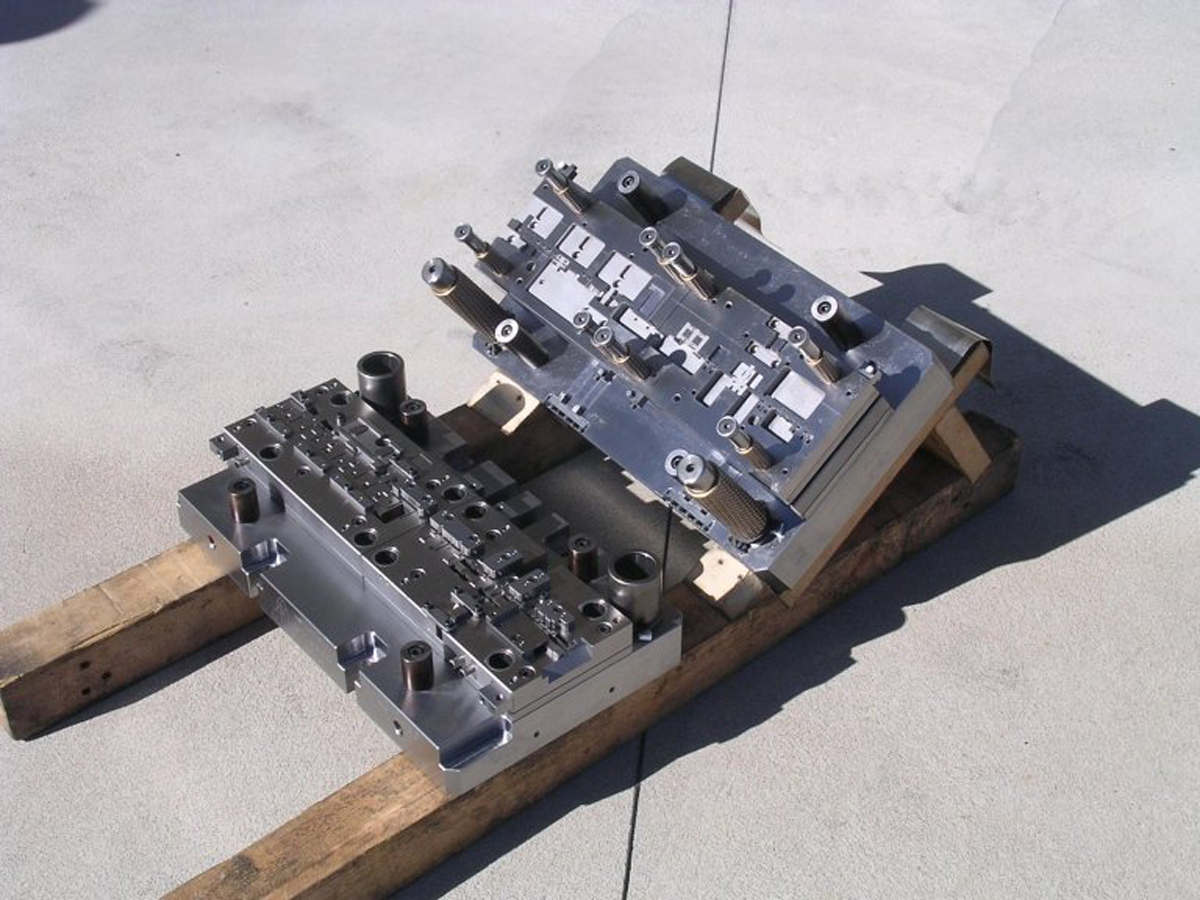

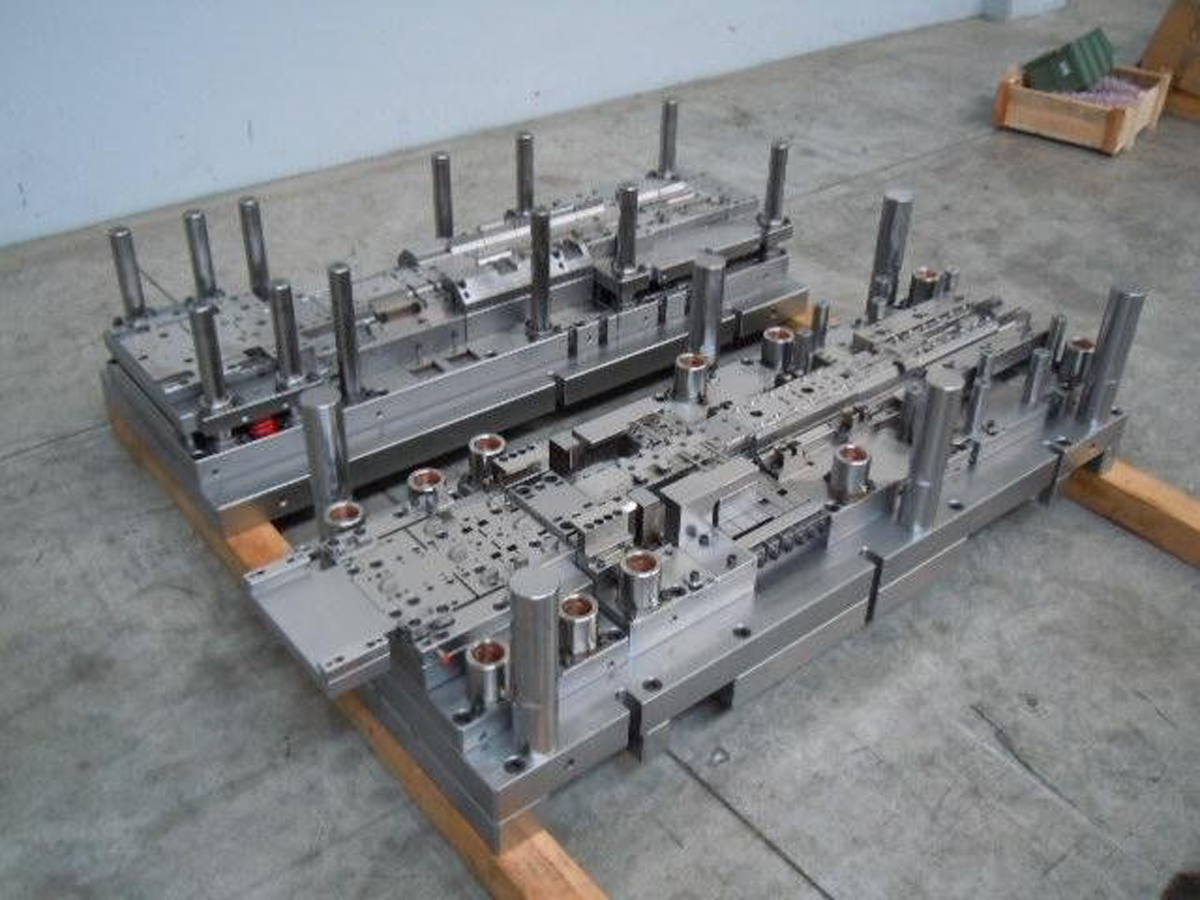

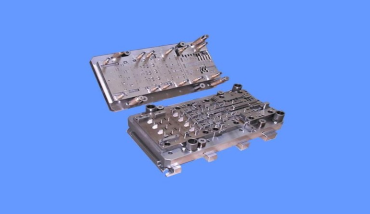

MOULDS

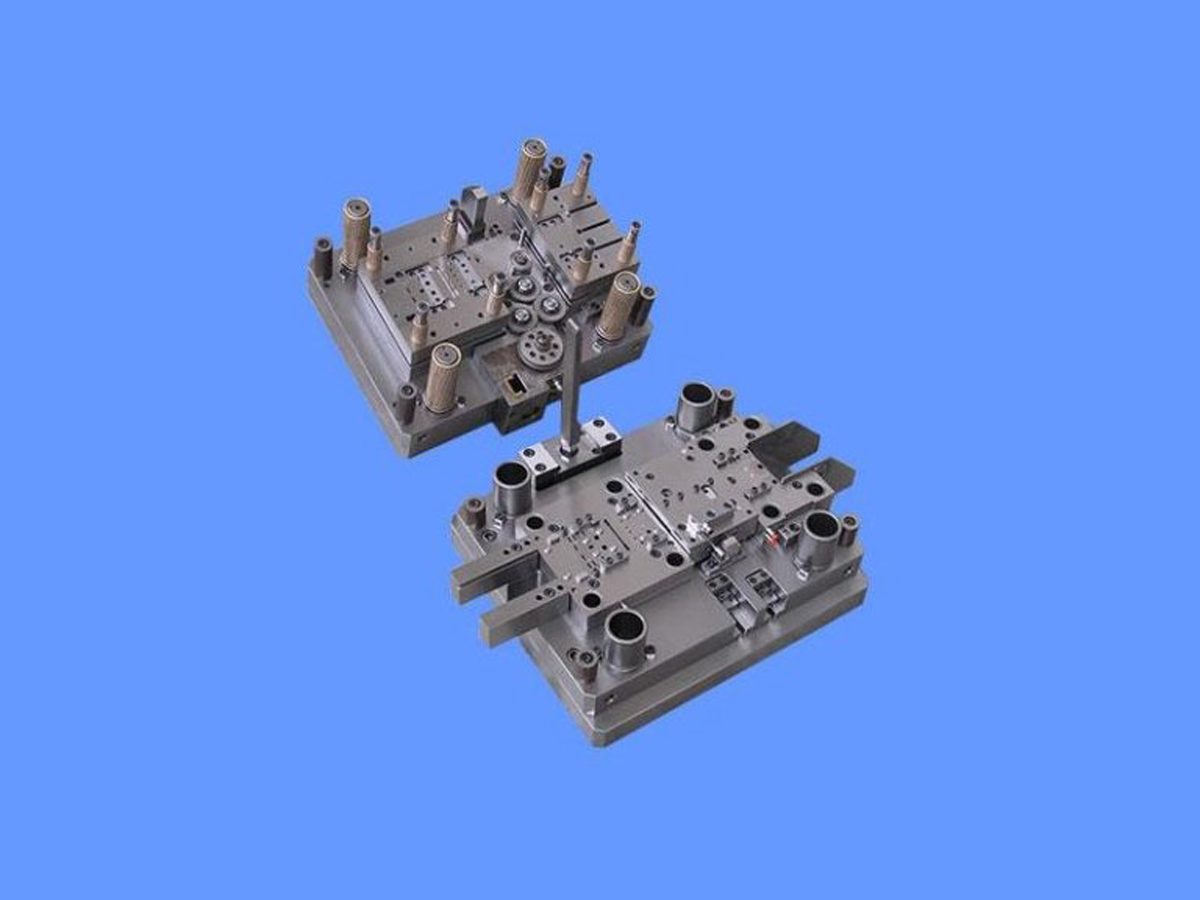

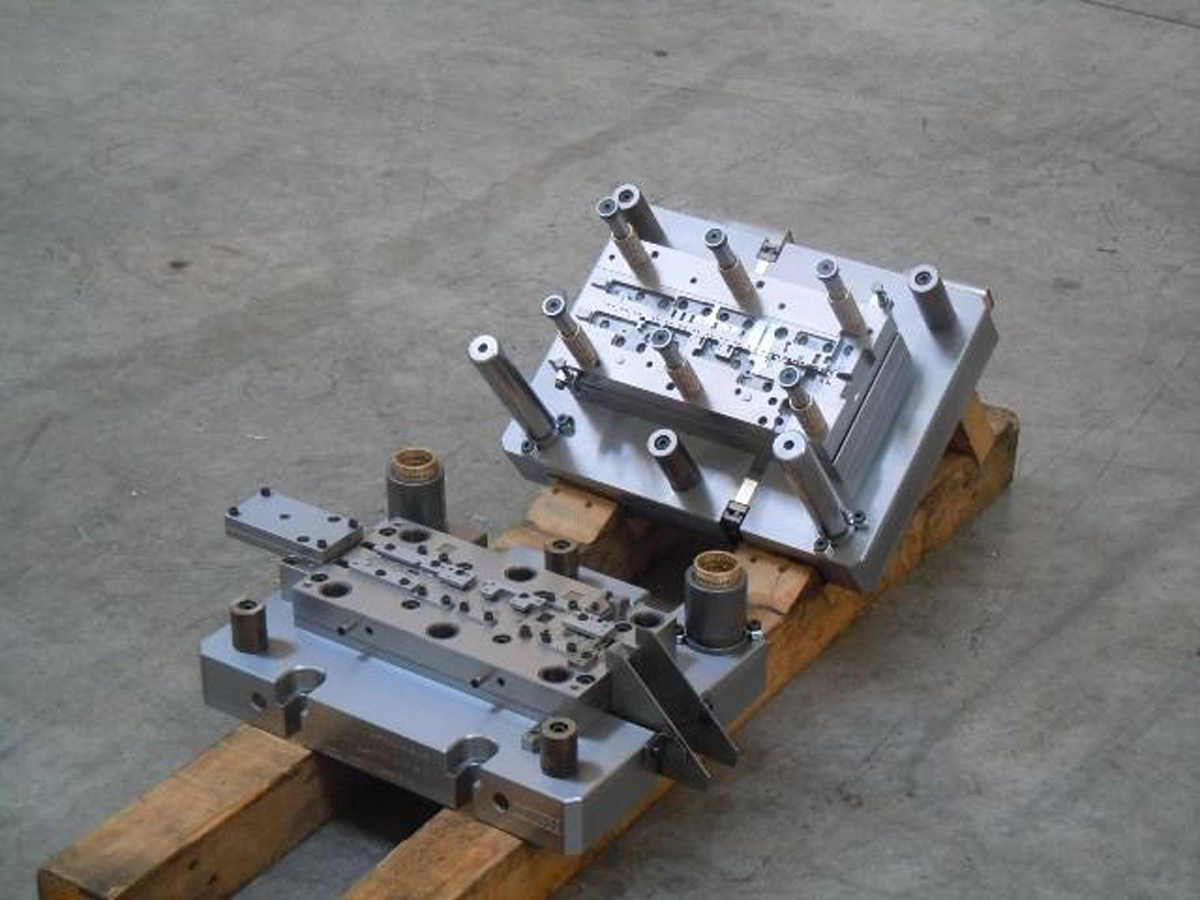

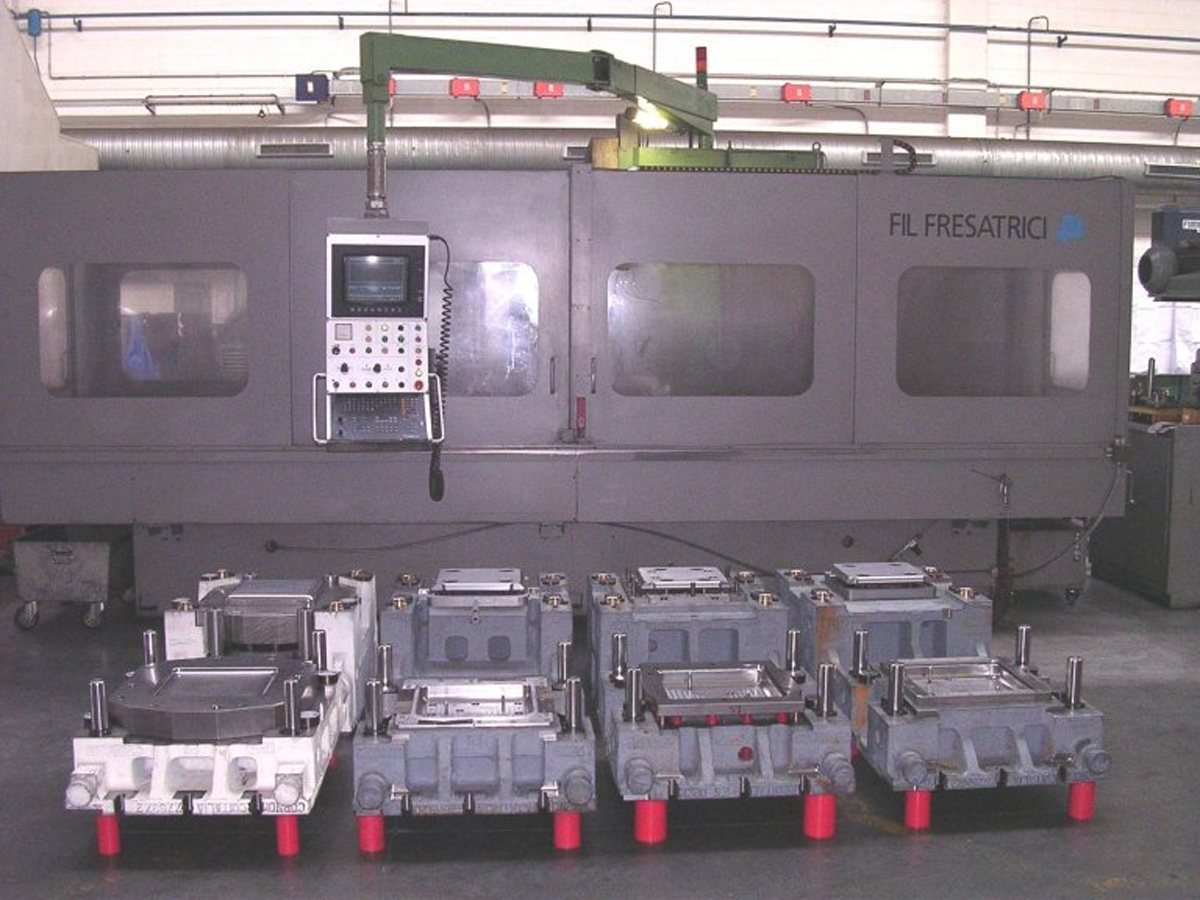

MOULD-MAKING

Longhi Stampi is also involved in mould making, using advanced CADCAM technology and modern design systems to produce finished products for all customers’ needs.

The moulds are completely company-made, from the design to the choice of raw materials, thanks to a large and articulated fleet. For more information on the moulds produced, the materials used or to request a customized quotation, please contact the company headquarters by phone or email.

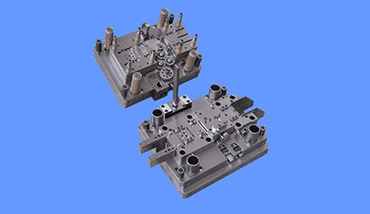

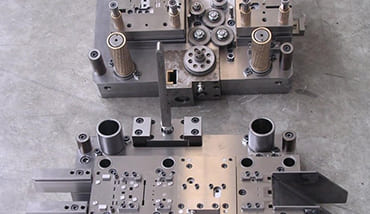

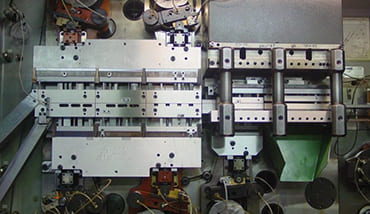

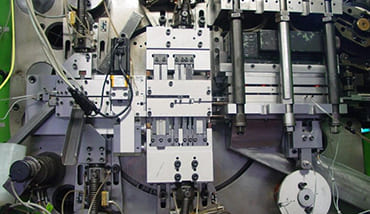

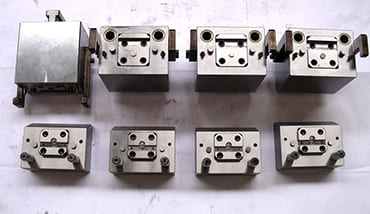

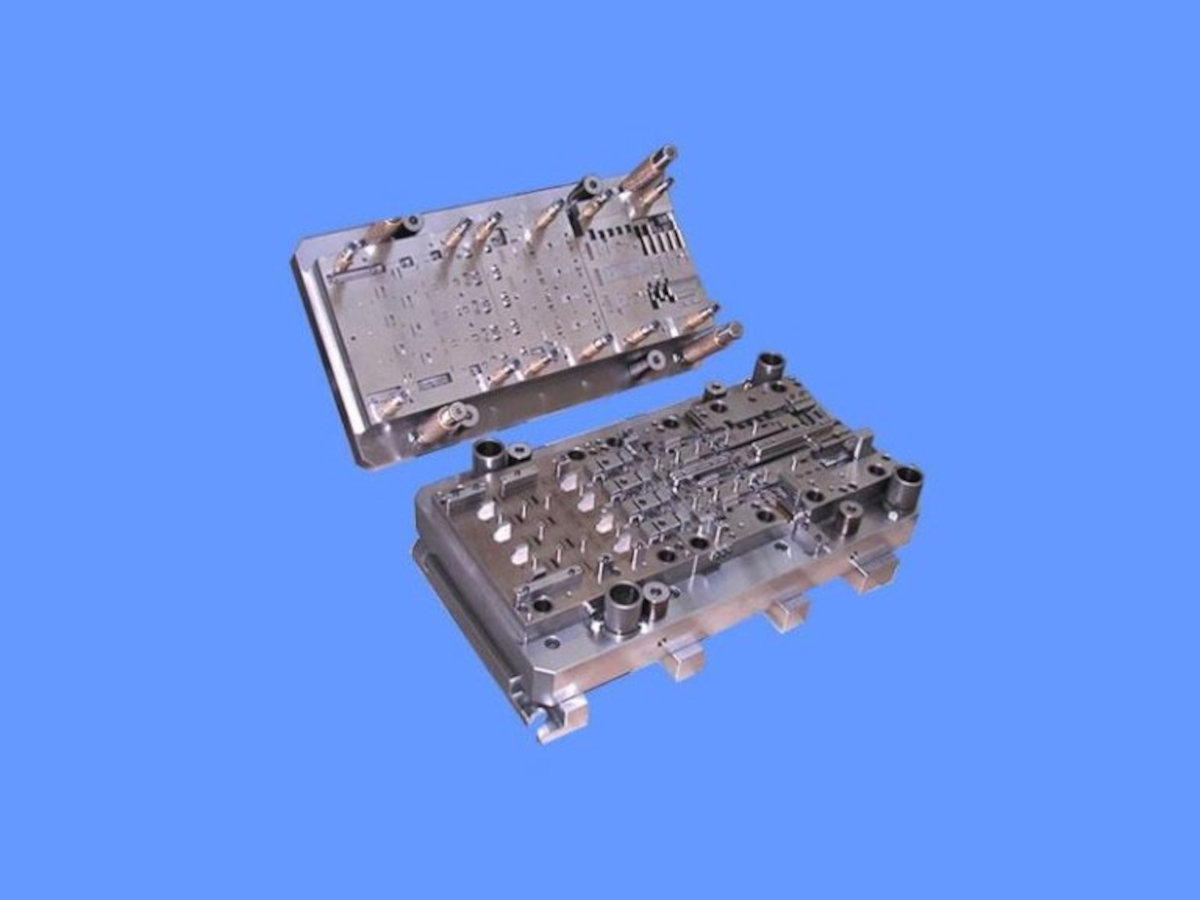

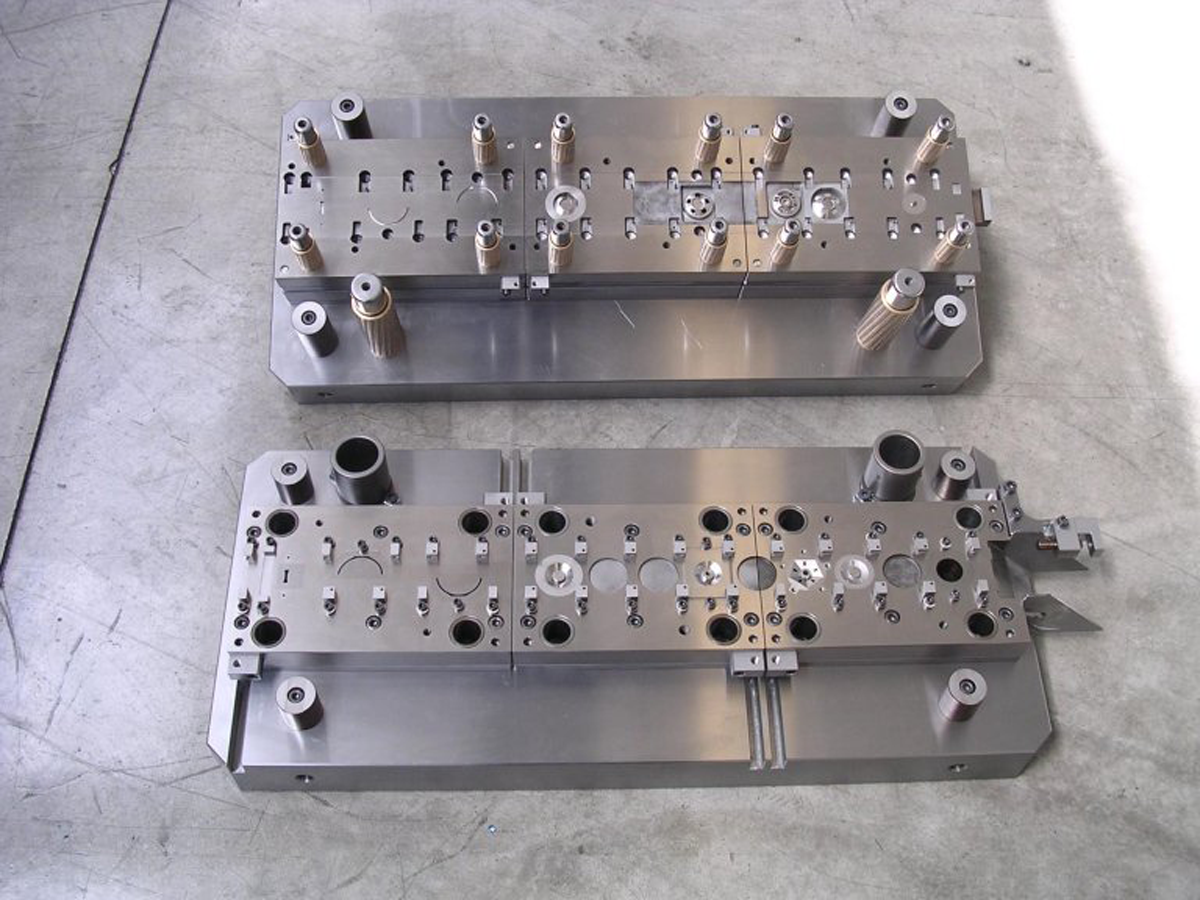

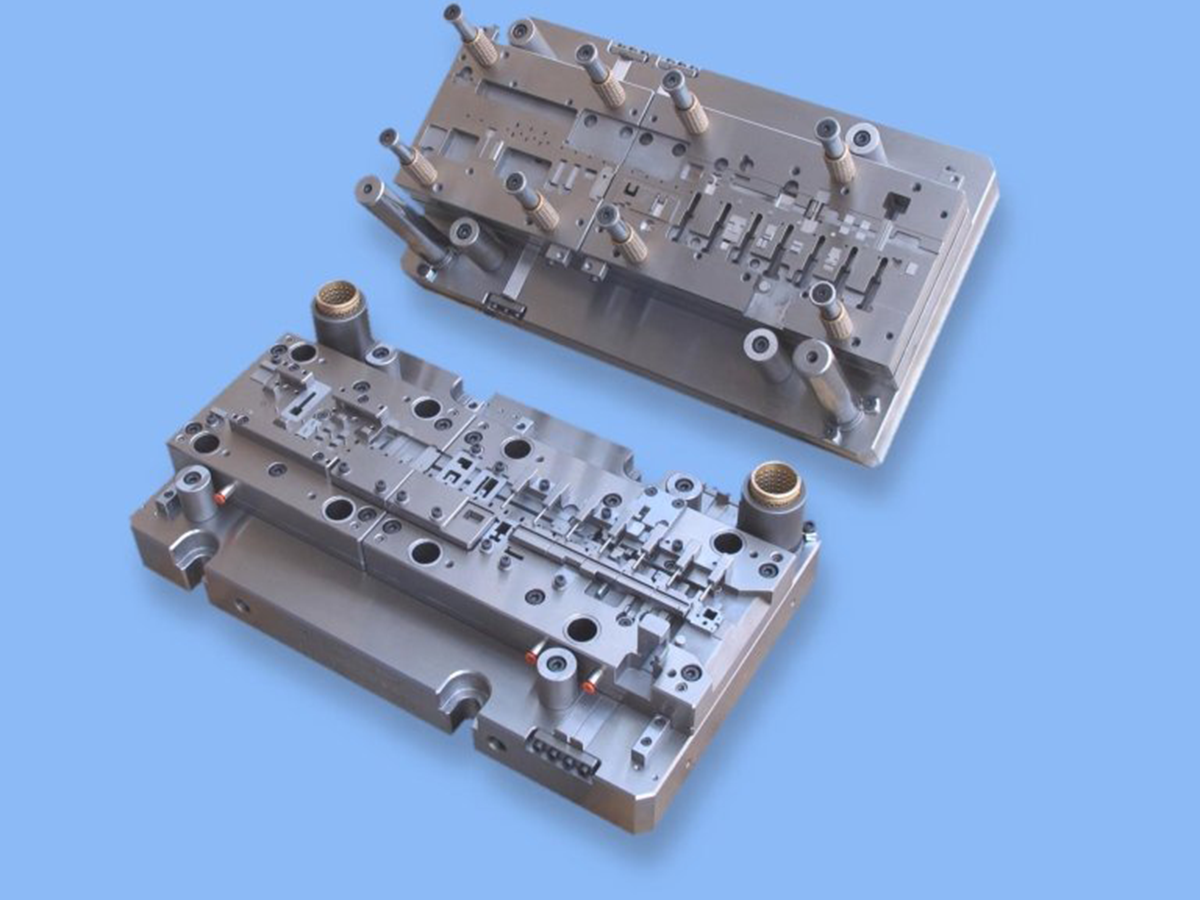

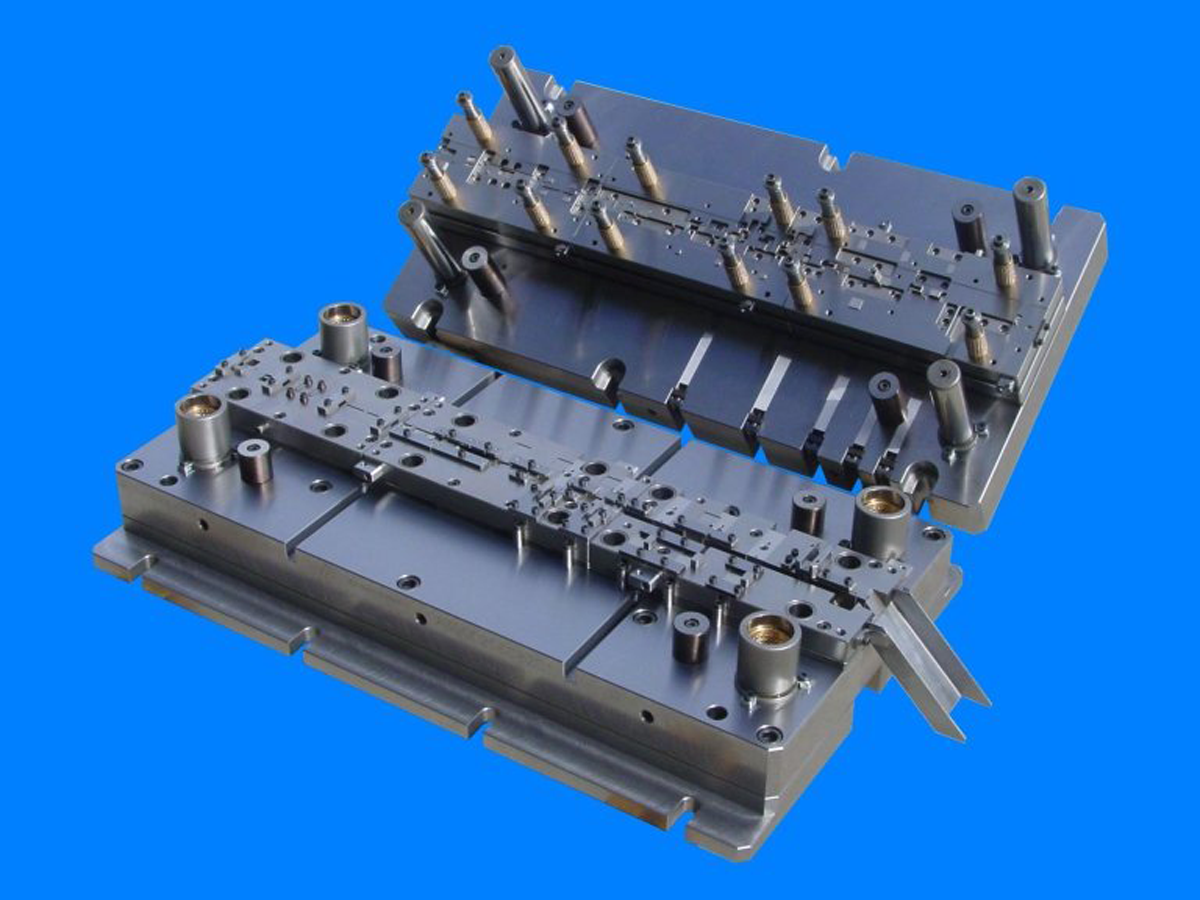

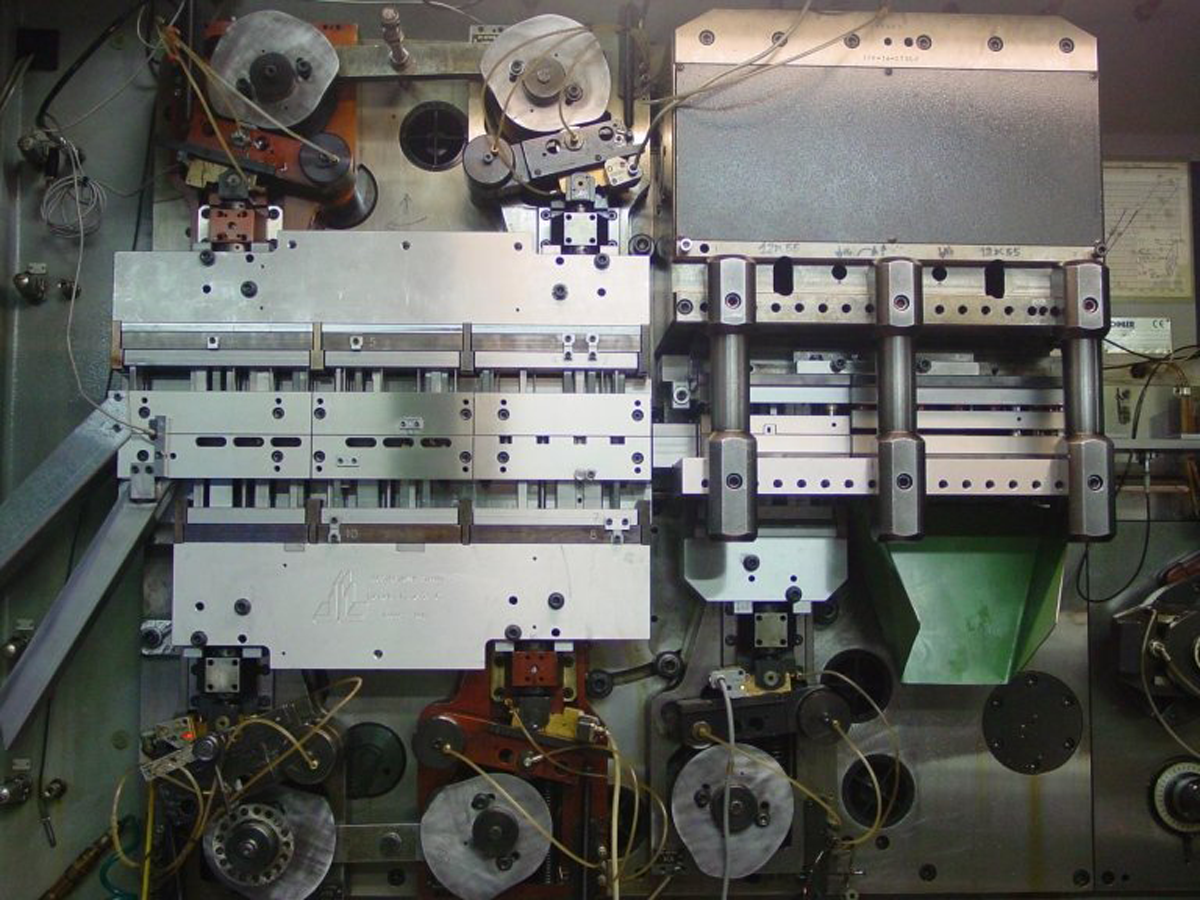

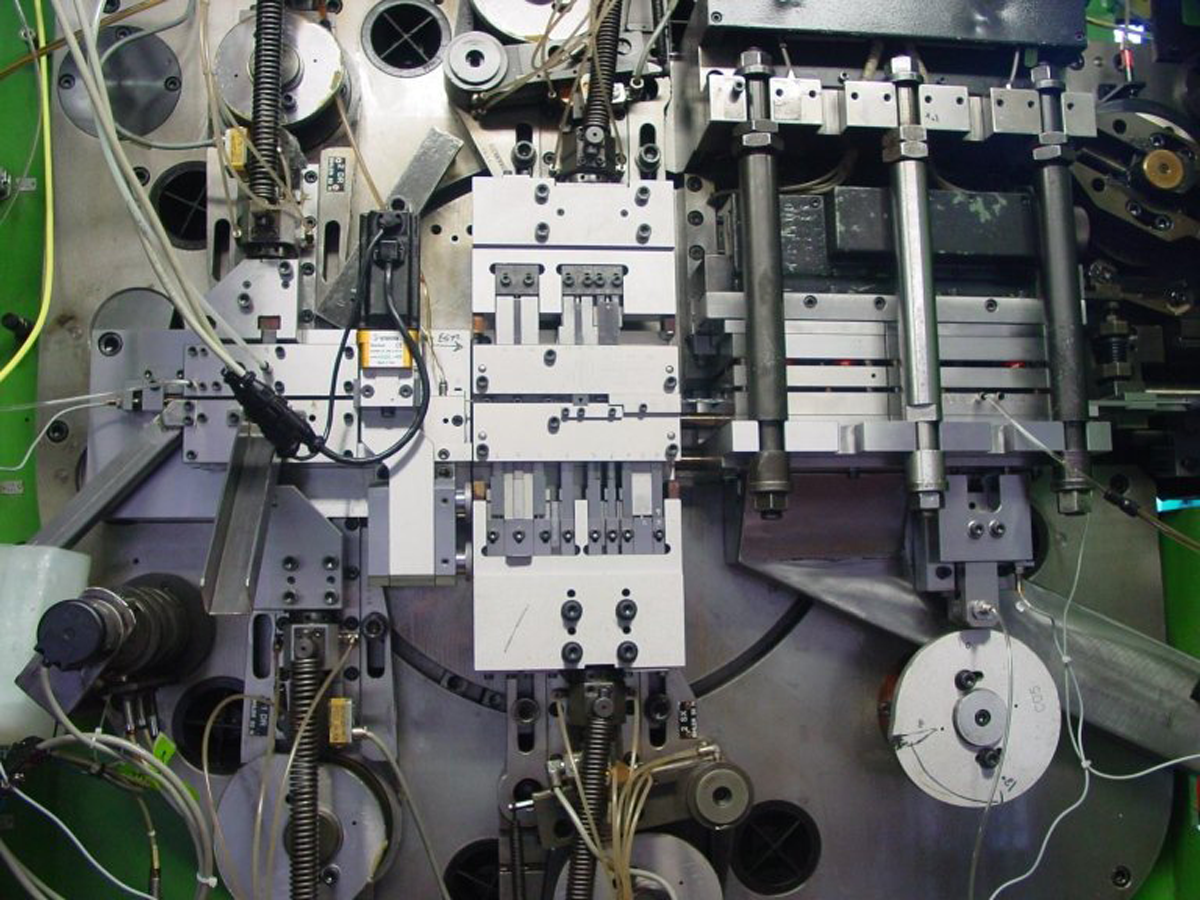

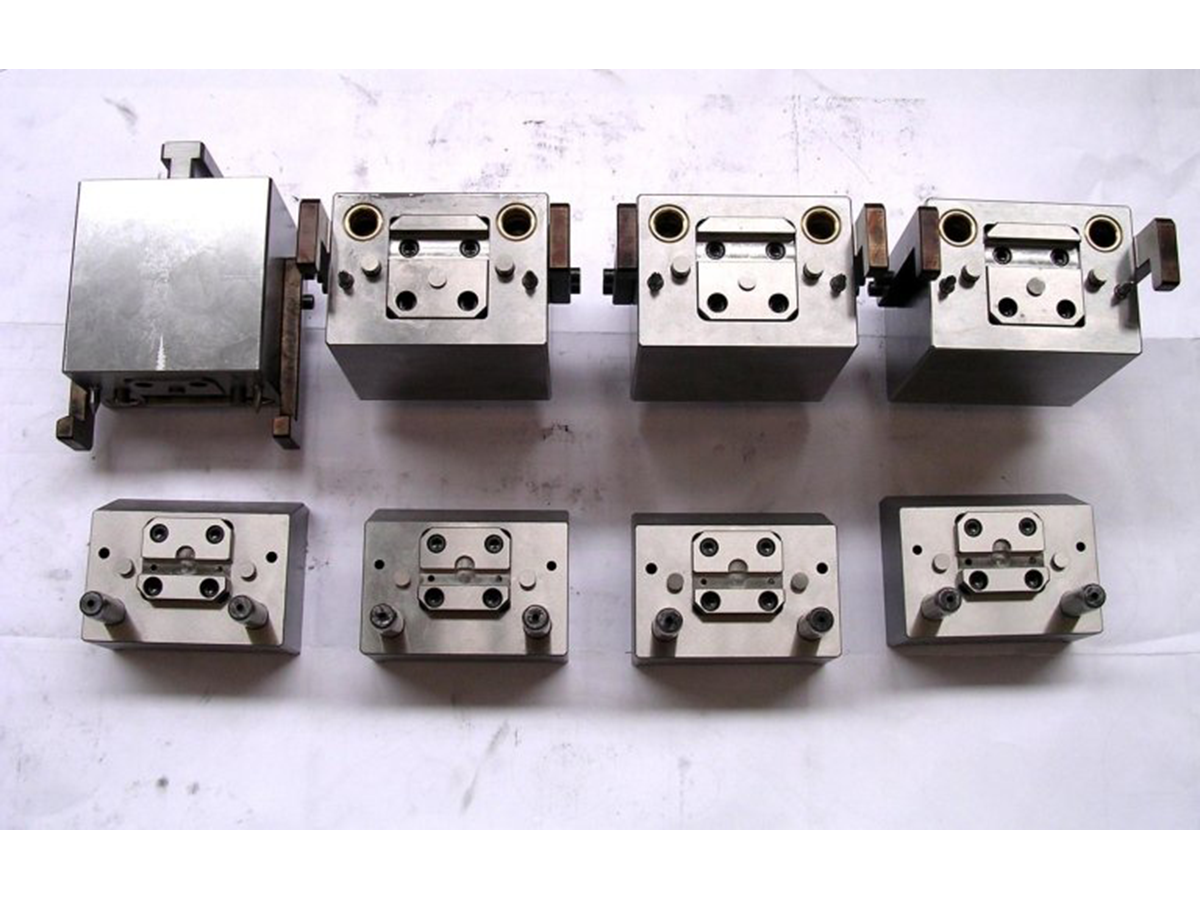

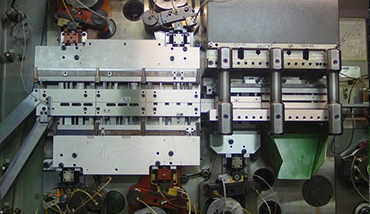

PROGRESSIVE MOULDS

- - Traditional moulds

- - High production moulds

- - Moulds for assemblies, carbide or steel fittings

- - Modular solutions that can be dismantled under press for an easy version change, grinding and maintenance

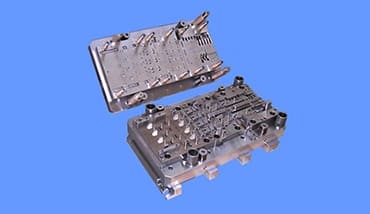

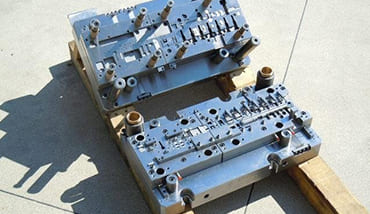

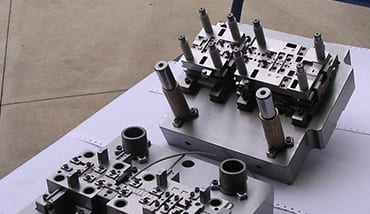

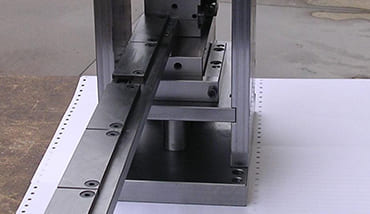

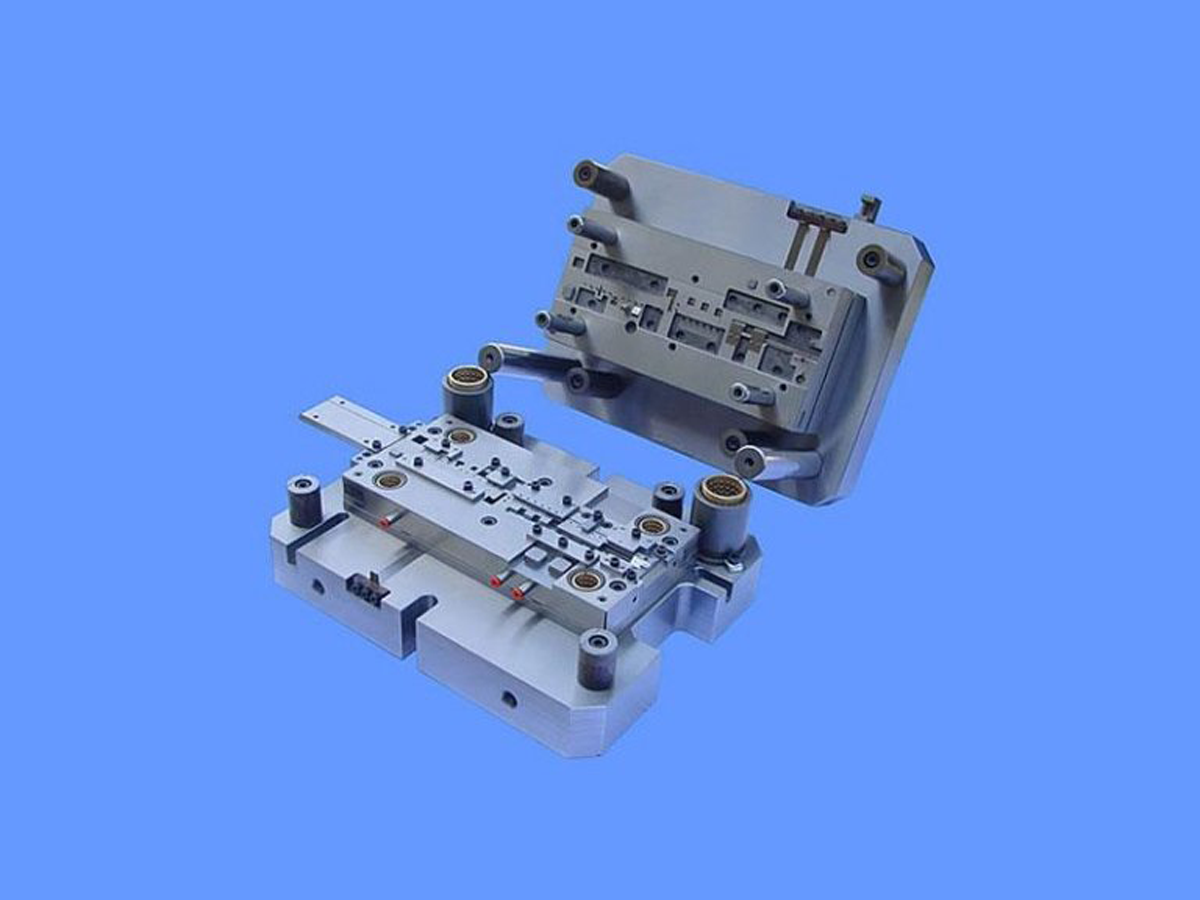

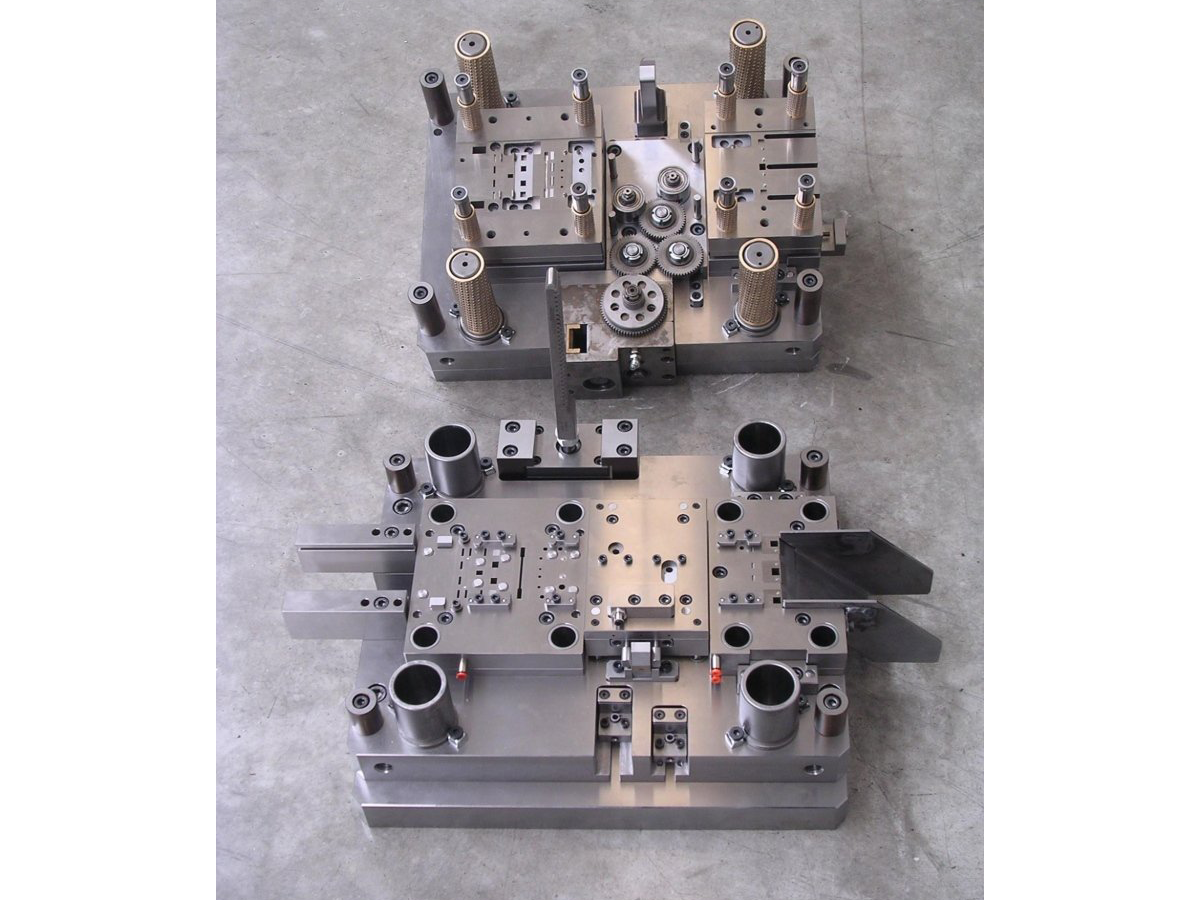

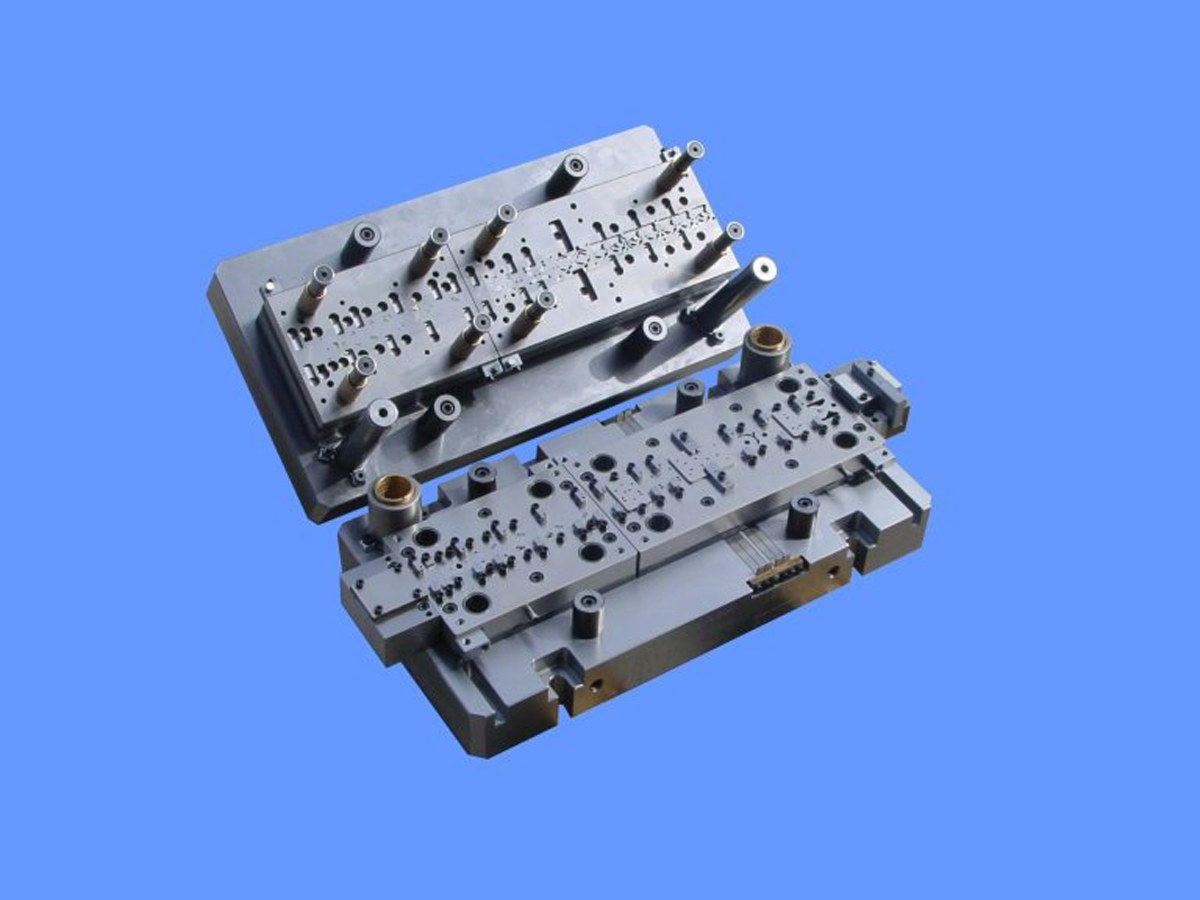

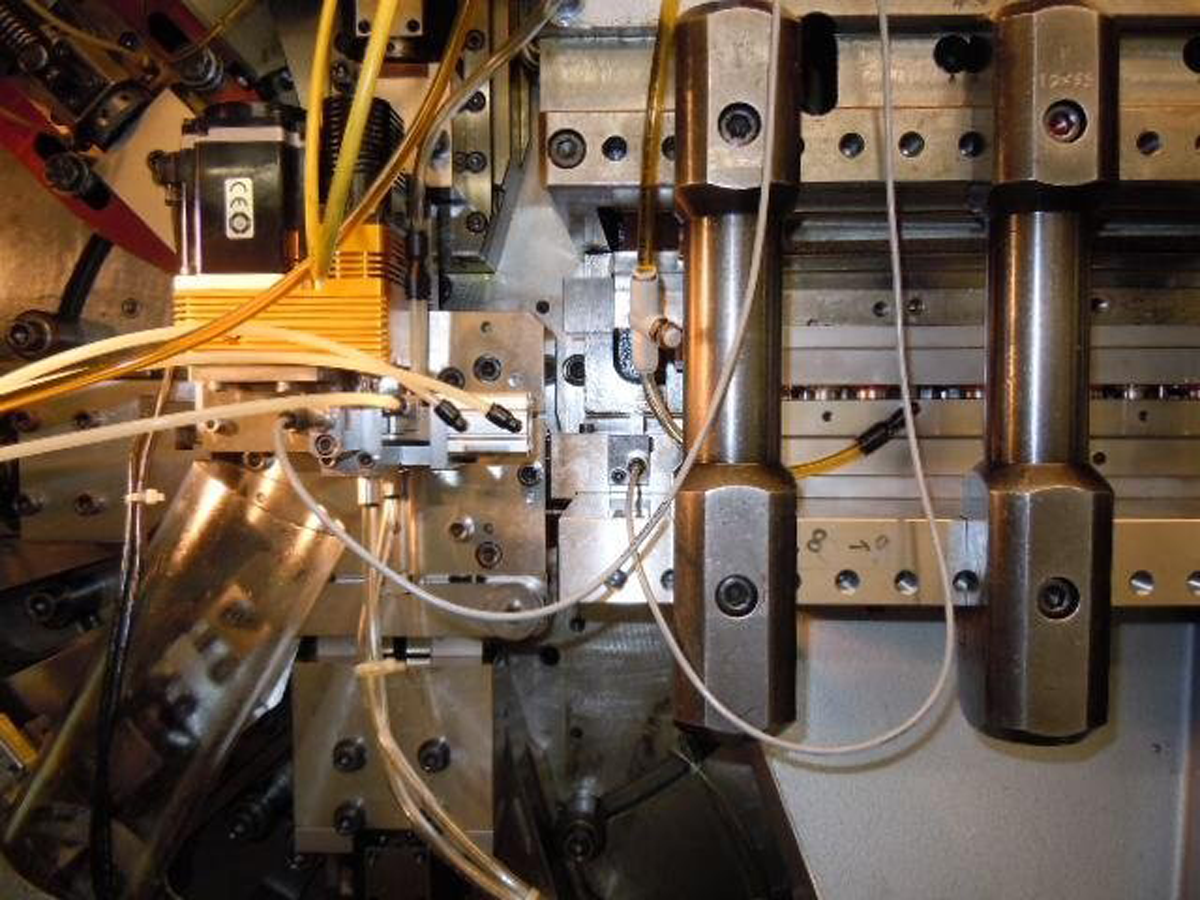

TRANSFER MOULDS

Recommended to optimize raw material consumption.

We produce transfer moulds thanks to modern technology.

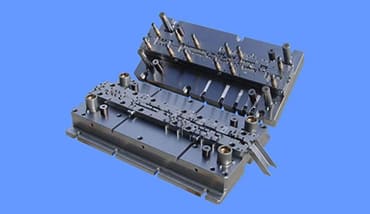

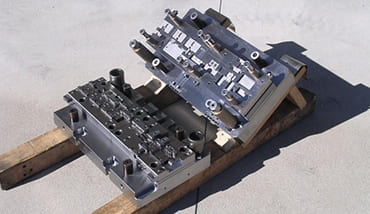

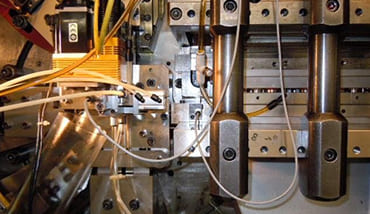

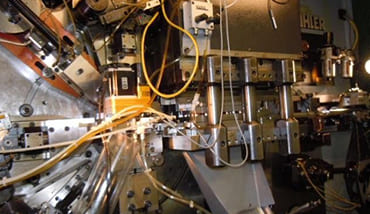

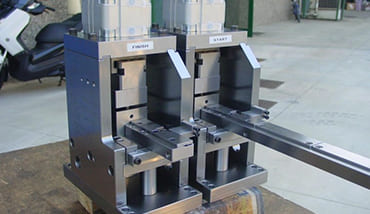

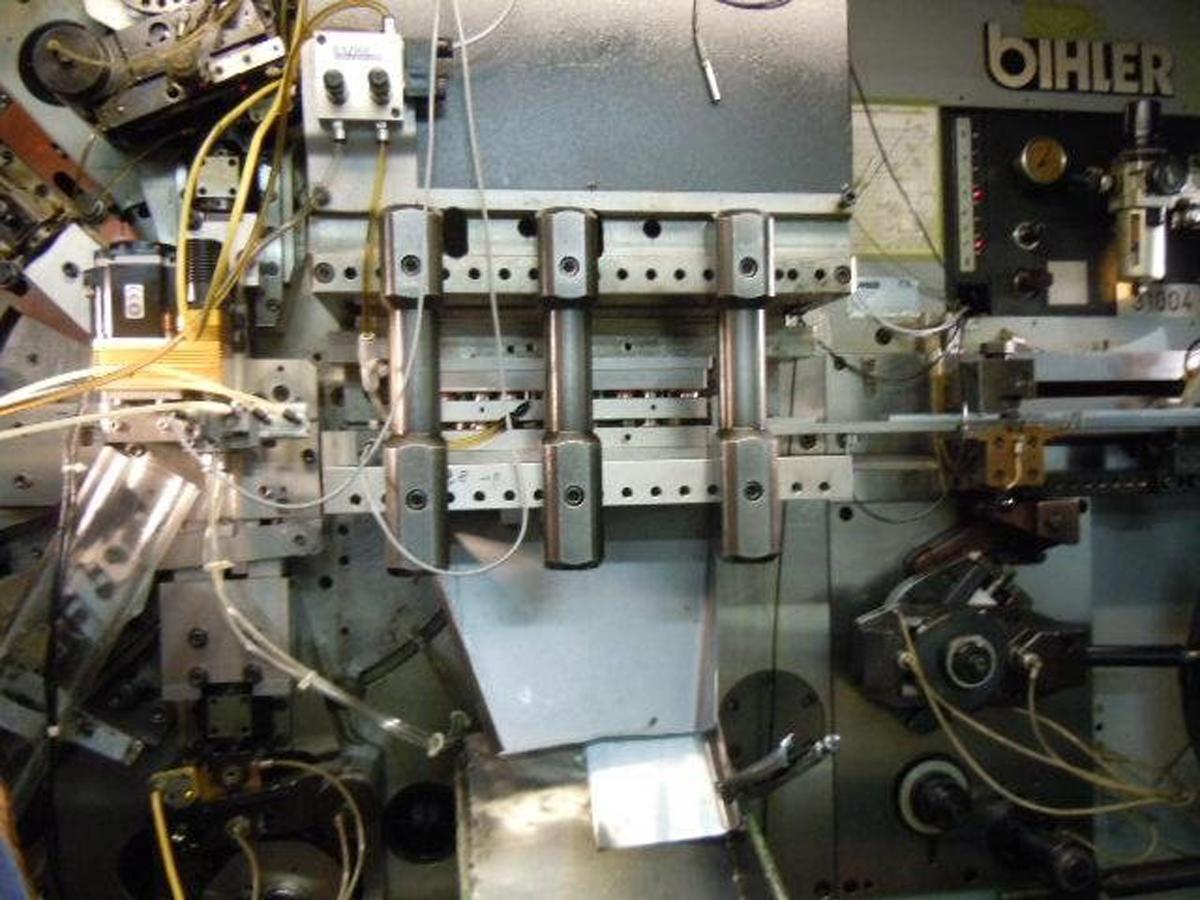

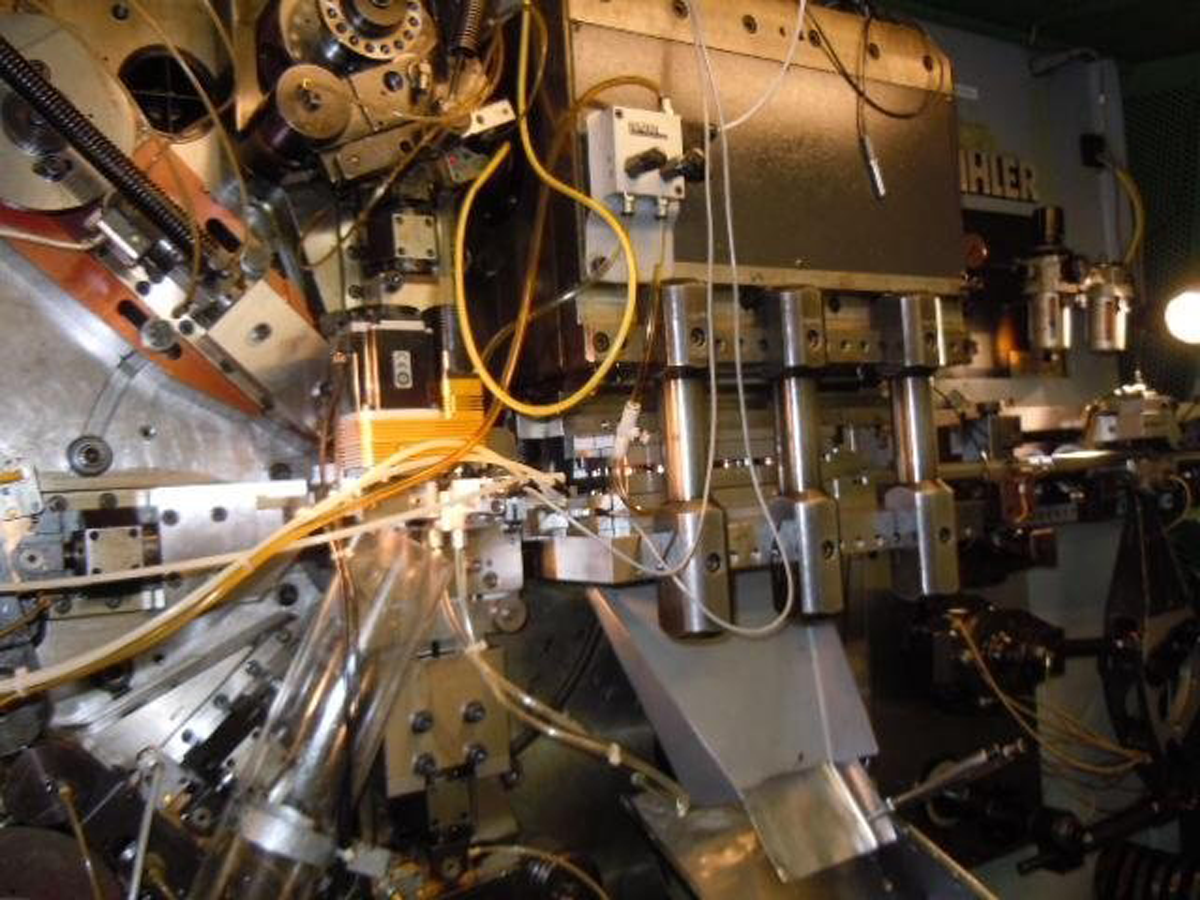

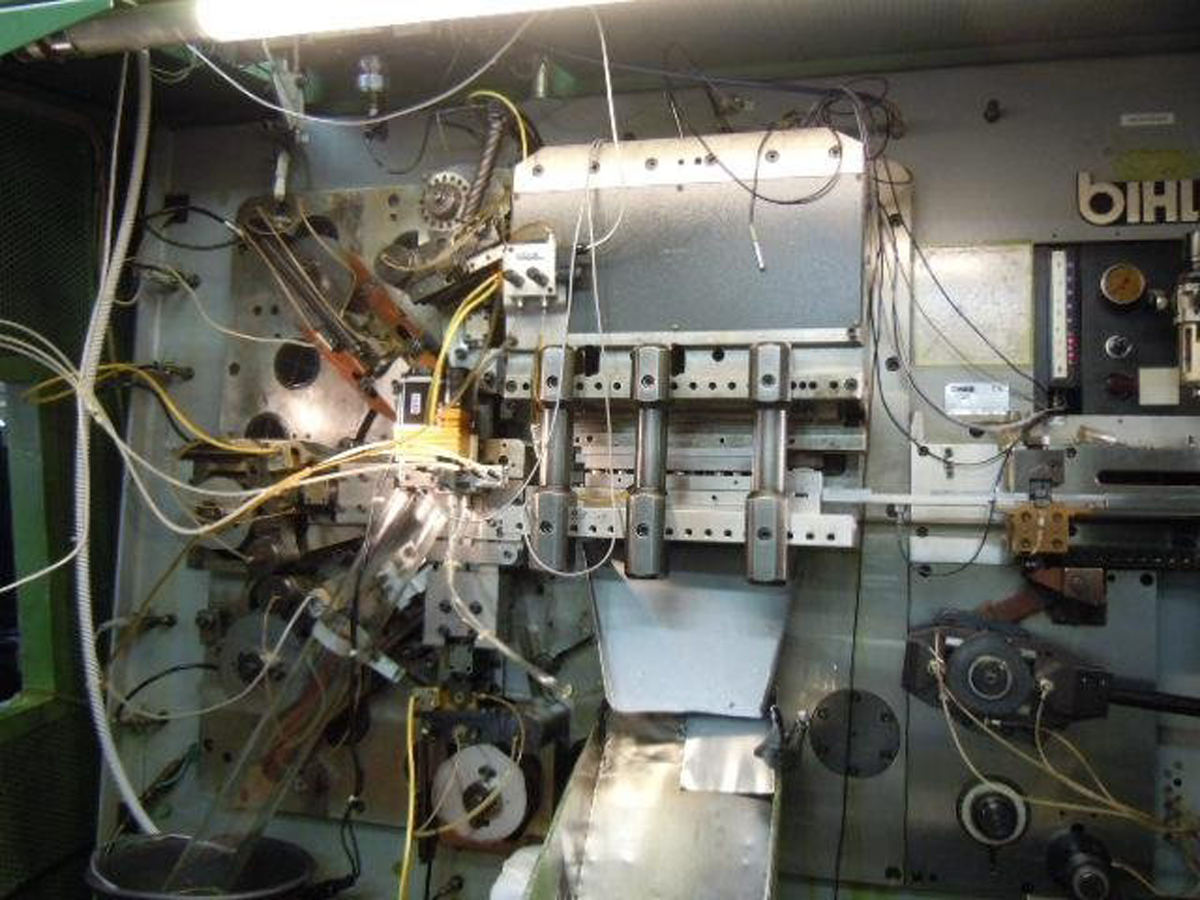

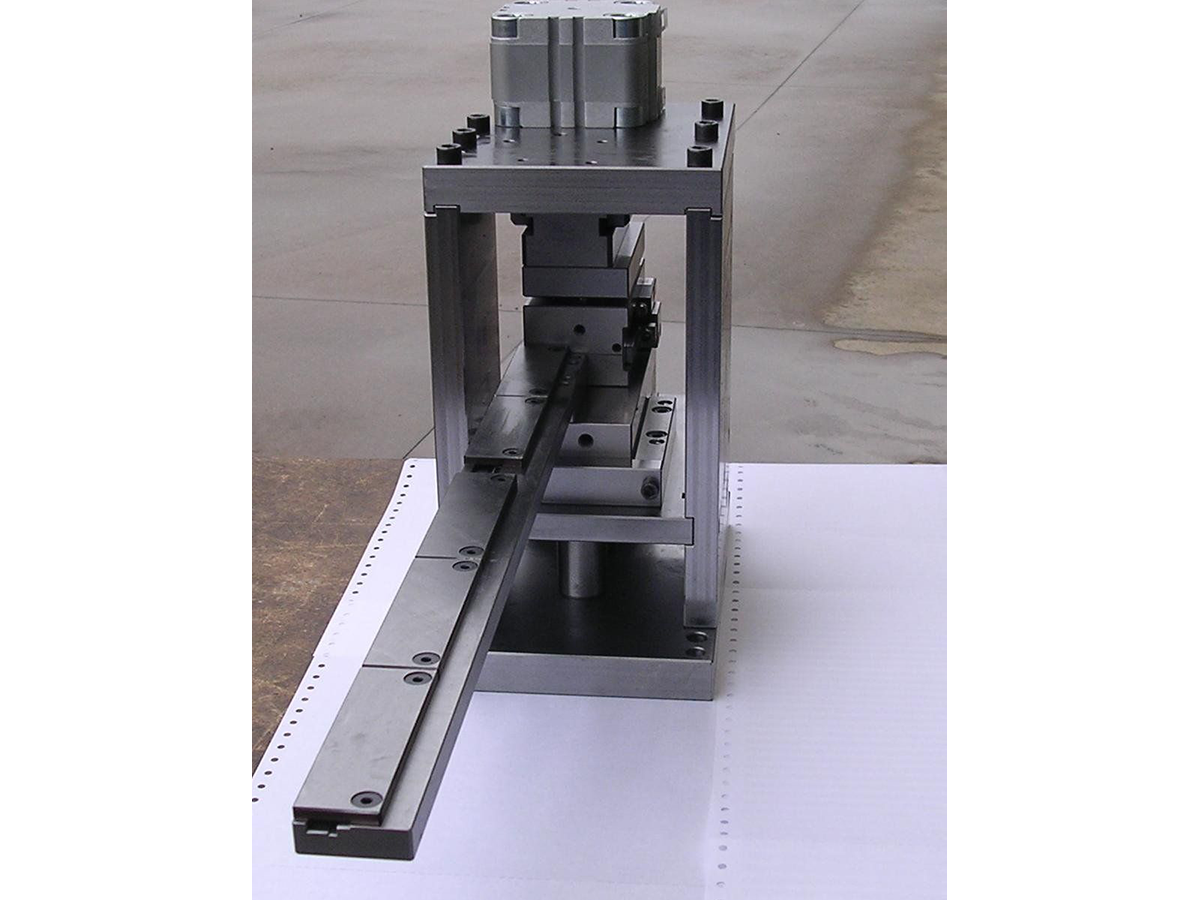

BIHLER - PRESSURE BENDING EQUIPMENT

- - Linear or radial equipment

- - Assembled pieces

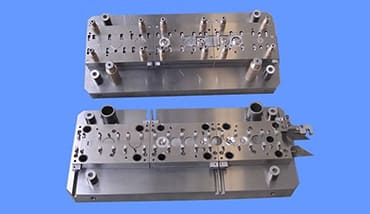

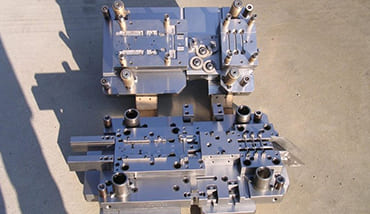

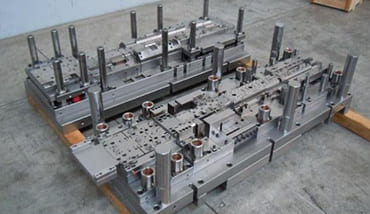

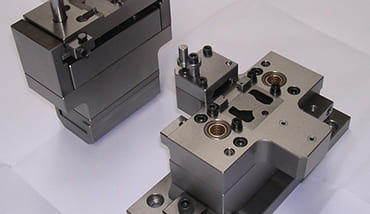

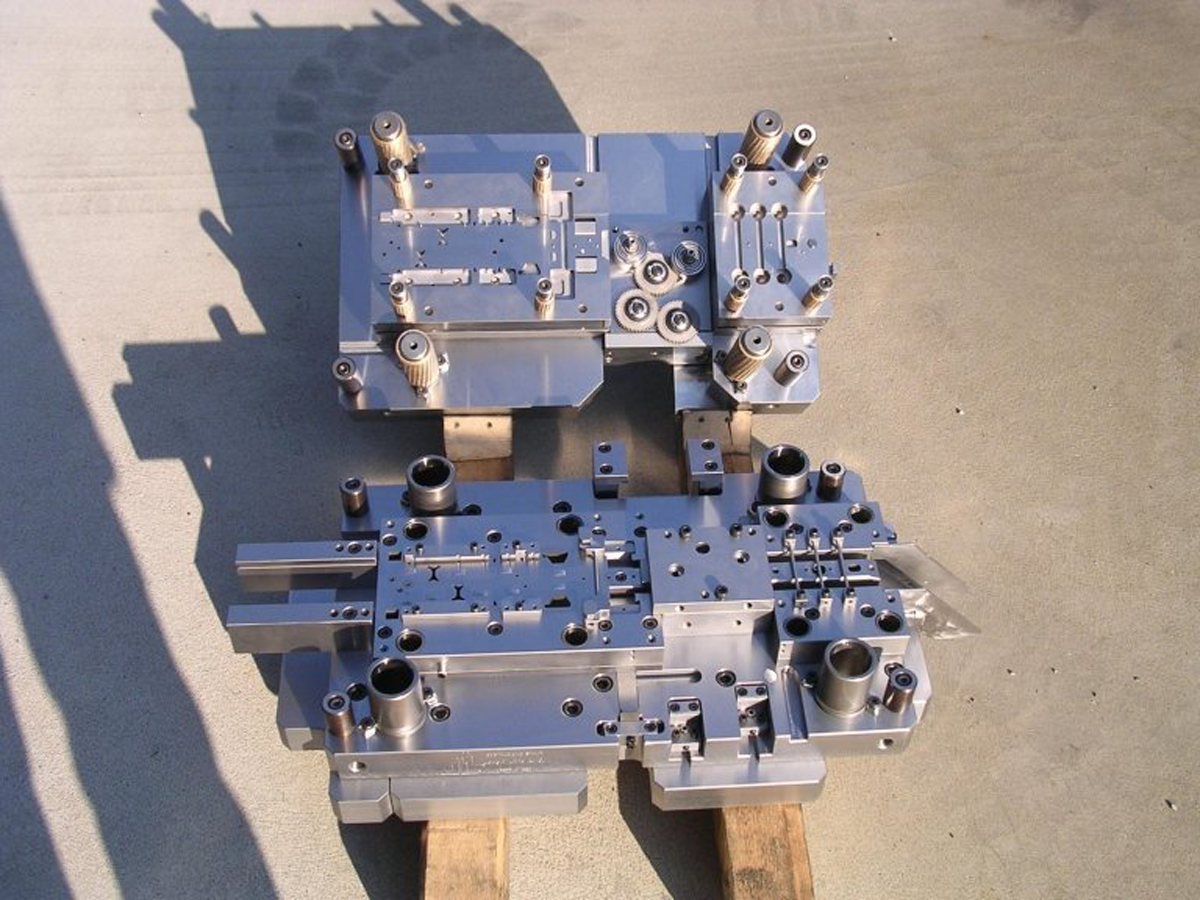

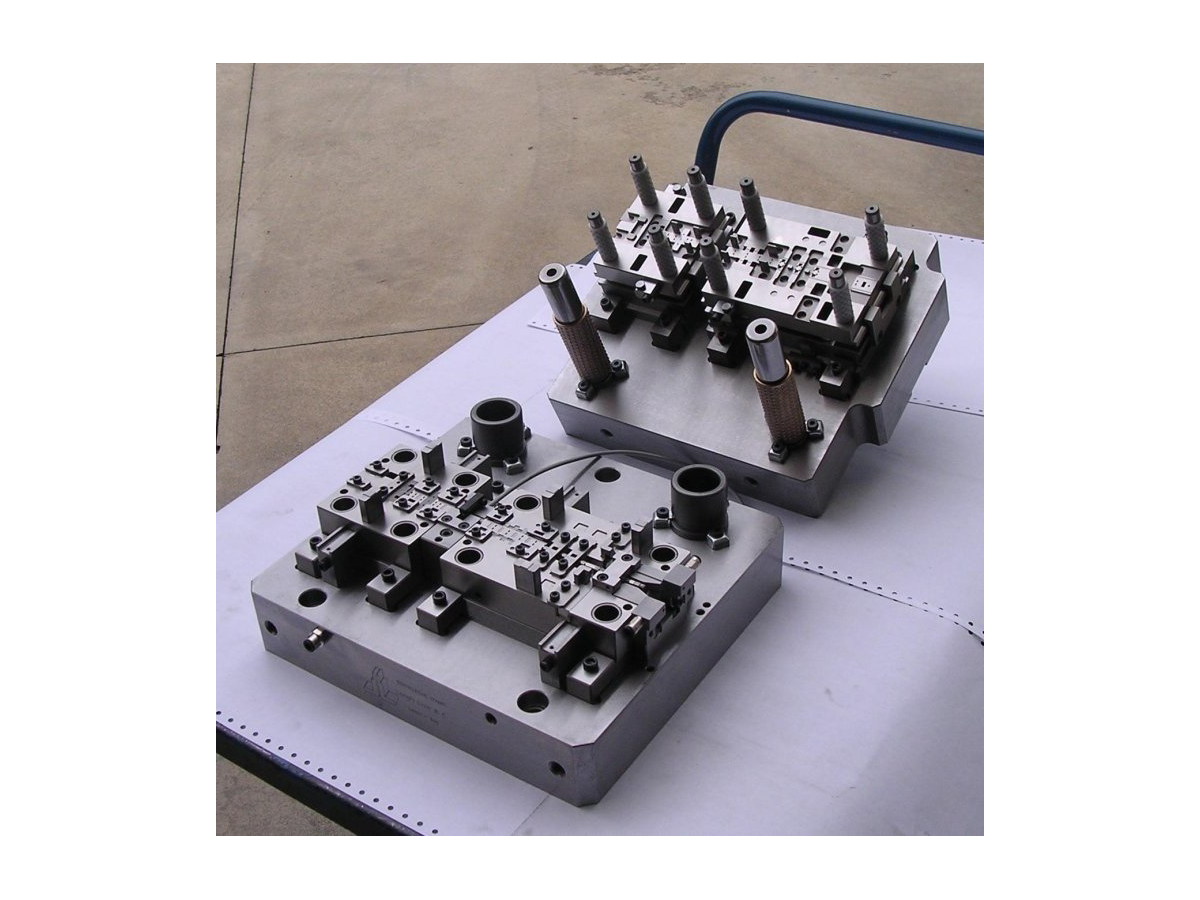

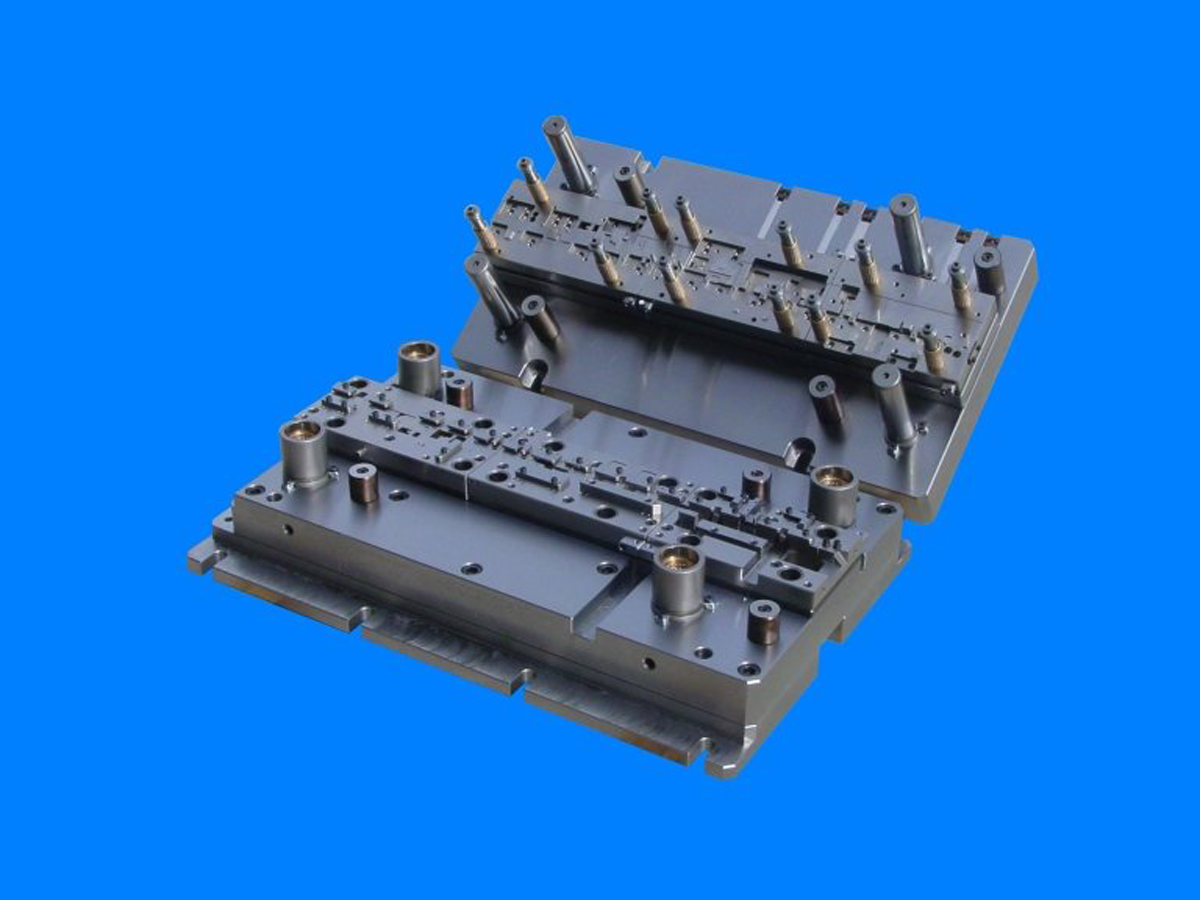

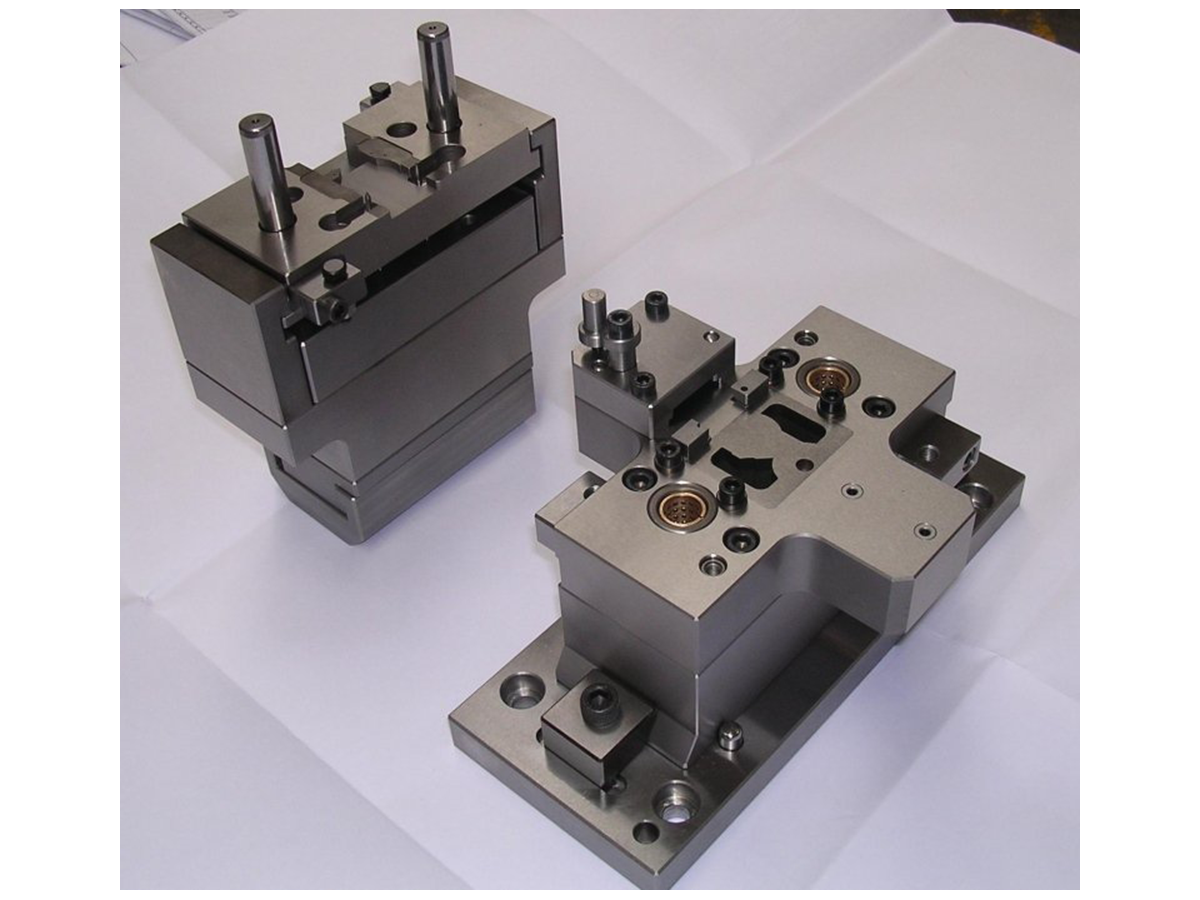

SPECIAL UNITS

Longhi Livio e C. s.a.s. is specialized in the design and development of special molding units.

The company, based in Lecco, supplies a wide range of:

The company, based in Lecco, supplies a wide range of:

- - Special units for workstations

- - Special units for assembly lines

- - Cutting dies for industrial use

- - Moulds for bending or any other operation

- - Pneumatic, hydro-pneumatic and mechanical presses

- - Cutting-edge pressing systems

- - Handling, gripping and assembly systems

and everything necessary to complete these tasks efficiently, quickly and safely. To receive more information, or for a customized quotation, please contact the offices in Lecco at the contact details you will find by clicking here.